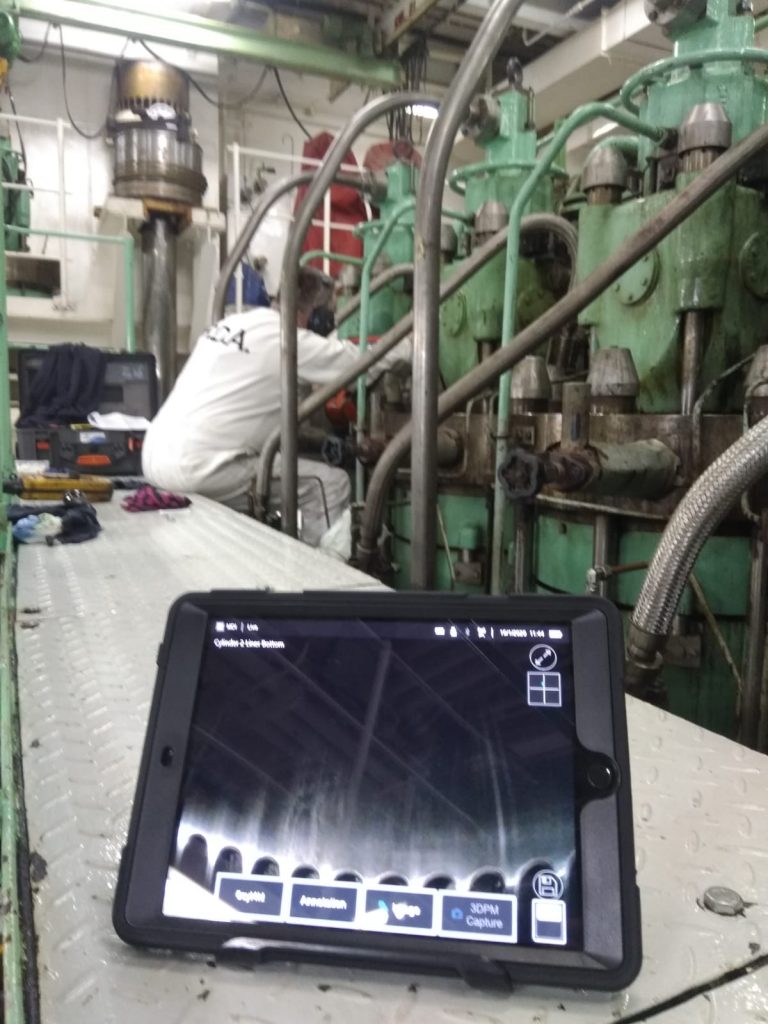

MViQ borescope 6 months in service: performance review

Now that the MViQ borescope inspection system has been used intensively by RDA Shiptech inspectors for almost 6 months, it is time for our first performance review.

Improved large bore and slow speed engine inspection quality

Thanks to the unmatched LED lighting power and image enhancing software, it now possible to inspect even larger cylinder bores with high accuracy. This will enable further growth of our RVI inspections in the two stroke market.

High temperature operation

Among the major challenges when inspecting engines shortly after shut down, are the high temperatures to which the camera is exposed. Our team developed dedicated air cooling adapters to increase the maximum inspection temperature, but temperature remained a critical aspect. The new MViQ system remains operable at higher temperatures, which has proven to be very useful shortly after shut down and in particular hot environments where cooling the engine is a challenge.

Quantification of defects and wear

One of the most impressive features of the MViQ system is the ability to measure a wide range of wear and defects at great accuracy. 3D depth maps can be generated instantaneously to measure for example valve hammering in an engine, the (rotor) tip clearance in a turbine or the length of a crack.